UMA TECHNO FAB

Uma Techno Fab, based in Ahmedabad, Gujarat, specializes in manufacturing food processing, chemical, and pharma machinery. They offer equipment for cleaning, grading, and sorting, along with custom solutions based on client specifications. The company also provides EPC services, plant overhauling, and maintenance for diverse industries.

Categoary

Products

Facility

Most Recent Post

Portfolio

Contact Info

+91 87359 33517

24/7 Support for Your Business

Info File

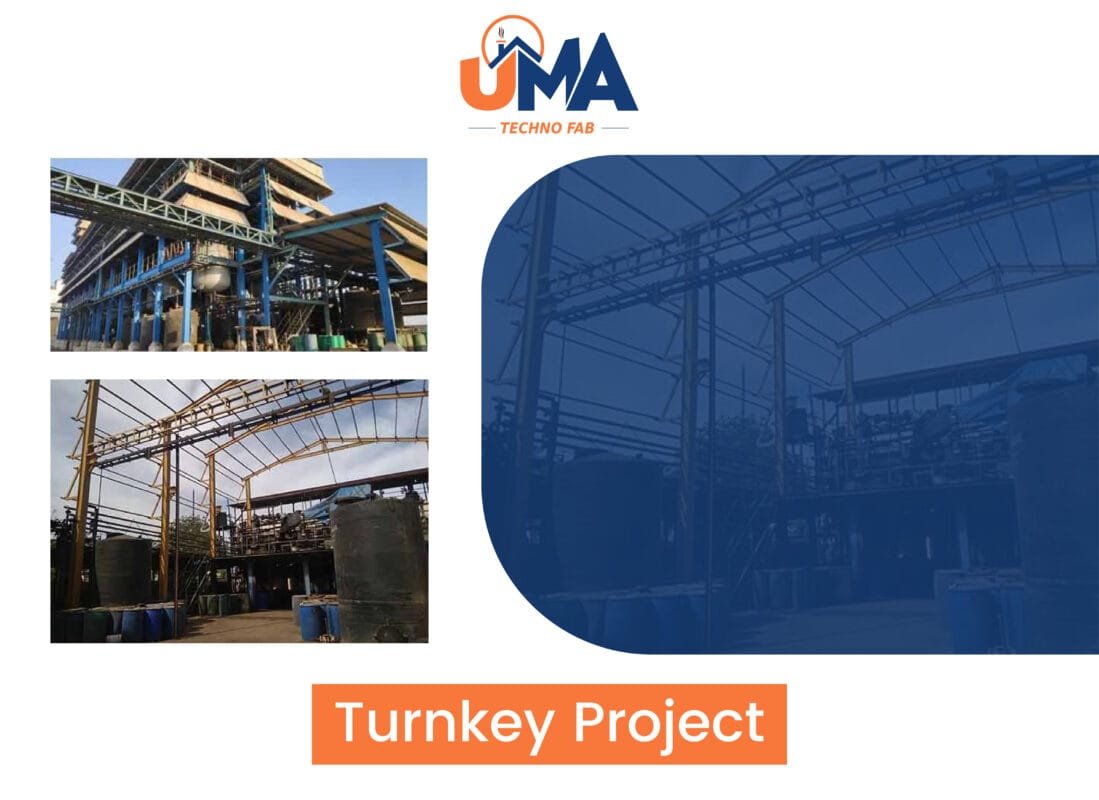

Overview :

A Turnkey Project is a complete, all-in-one solution designed for food manufacturing and processing. It encompasses every stage, including planning, design, equipment manufacturing, installation, and commissioning. With a turnkey approach, clients receive a fully operational production system tailored to their unique needs. These projects are ideal for companies looking to establish new food processing plants, upgrade existing facilities, or expand production lines efficiently and effectively.

Turnkey projects ensure seamless integration of equipment and processes, saving time and eliminating the challenges of coordinating multiple vendors.

Key Features:

- Turnkey projects provide complete support from conceptualization to execution, including design, manufacturing, installation, testing, and operational training.

- Each project is tailored to the client's specific requirements, ensuring optimal productivity, compliance with industry standards, and seamless integration into existing workflows.

- The machinery used in turnkey projects is manufactured using premium-grade materials and incorporates the latest technological advancements for reliability and efficiency.

- Integration of PLC systems, IoT connectivity, and automation ensures precise control, reduced human intervention, and enhanced productivity.

- All equipment and processes are designed to meet HACCP, ISO, and other international food safety regulations, ensuring safe and hygienic production.

- Turnkey systems are designed with scalability in mind, allowing for easy future expansion and adaptability to changing production requirements.

- Dedicated teams handle on-site installation, testing, and commissioning. They also provide operational training for staff to ensure smooth transitions.

Advantages :

- Simplified Project Execution

- Time Efficiency

- Cost-Effectiveness

- Consistent Quality

- Future-Ready Systems

- Comprehensive After-Sales Support

- Reduced Operational Downtime

With a single point of responsibility, turnkey solutions eliminate the need to coordinate with multiple vendors, streamlining project execution.

Turnkey projects are planned and executed with a focus on meeting deadlines, enabling clients to start operations faster.

By bundling all services into one project, clients save on costs associated with vendor coordination, delays, and unforeseen expenses.

Since a single team oversees every aspect of the project, clients can expect uniform quality in both equipment and processes.

Turnkey solutions are designed to accommodate future technological advancements and increased production demands, making them a long-term investment.

Clients benefit from ongoing support for maintenance, troubleshooting, and system upgrades, ensuring reliable performance over time.

By integrating high-quality equipment and automated systems, turnkey projects reduce downtime and boost overall productivity.