UMA TECHNO FAB

Uma Techno Fab, based in Ahmedabad, Gujarat, specializes in manufacturing food processing, chemical, and pharma machinery. They offer equipment for cleaning, grading, and sorting, along with custom solutions based on client specifications. The company also provides EPC services, plant overhauling, and maintenance for diverse industries.

Categoary

Products

Facility

Most Recent Post

Portfolio

Contact Info

+91 87359 33517

24/7 Support for Your Business

Info File

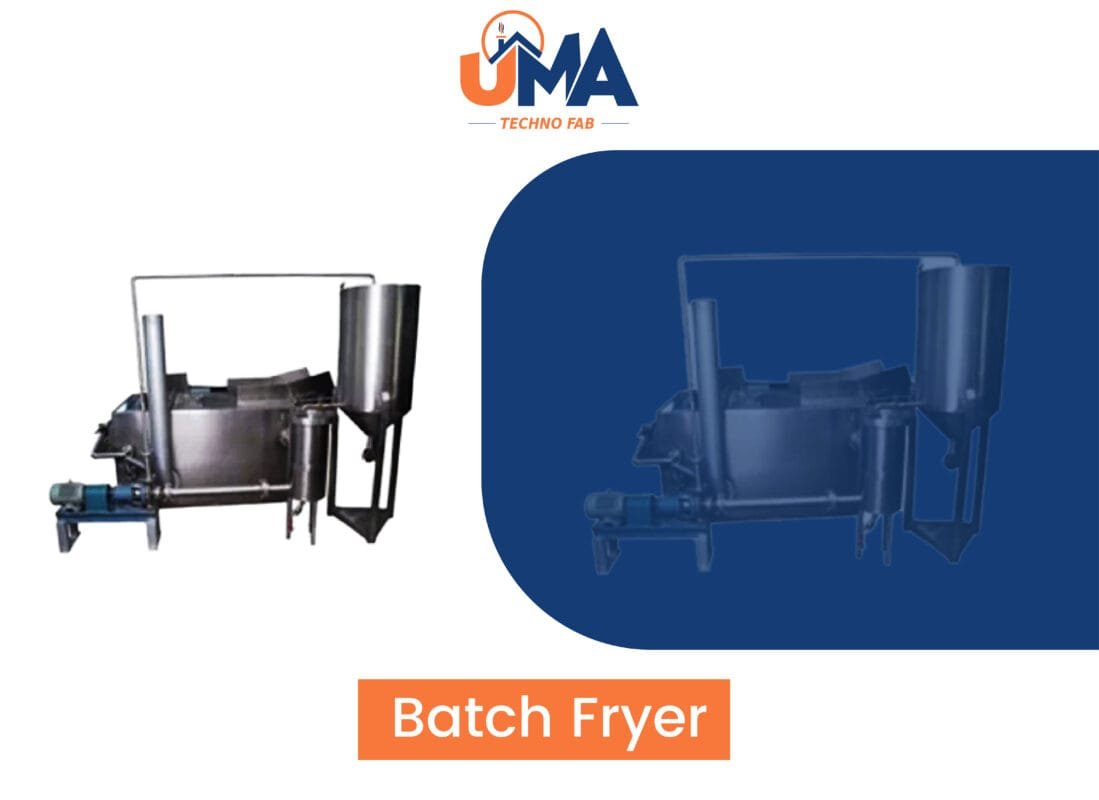

Overview :

The Batch Fryer is a specialized food processing machine designed for frying food products in controlled batches. It is widely used in the food industry for frying snacks, nuts, namkeen, and other fried food items with consistent quality and efficiency. Built with high-grade stainless steel, the machine ensures hygiene, durability, and food safety. Its versatile heating options—such as gas, diesel, thermic fluid, or electricity—make it adaptable for different production needs. This fryer is ideal for small to medium-scale food manufacturers aiming for uniform frying with reduced oil usage and enhanced energy efficiency.

Key Features:

- Made of stainless steel (SS 304/316) for food-grade safety and longevity.

- LPG/PNG Gas

- Diesel

- Thermic Fluid

- Electric

- Integrated oil circulation and filtration system to extend oil life and maintain product quality.

- Advanced temperature monitoring and control for precise frying and consistent results.

- Designed to handle food in controlled batches for small to medium production capacities.

- Optimized heating mechanisms to reduce fuel or energy consumption.

- Available in various capacities to meet specific production requirements.

- User-friendly controls and low-maintenance design for seamless operation.

- Simplifies cleaning and maintenance of the frying line to ensure hygiene and operational efficiency.

- Space-efficient design that minimizes floor space while delivering high output.

Advantages :

- Consistent Quality

- Cost-Effective

- Versatile Applications

- Hygienic & Safe

- Longer Oil Life

- Scalability

- Reduced Labor

Ensures uniform frying, resulting in better taste, texture, and appearance.

Reduces oil wastage, energy consumption, and overall operational costs.

Suitable for frying a variety of food items such as snacks, namkeen, chips, nuts, and sweets.

Stainless steel construction ensures hygiene and food safety compliance.

Integrated oil filtration system prevents oil degradation and extends its usability.

Perfect for businesses looking to scale from small to medium-sized production.

Semi-automatic operation reduces manual effort and increases efficiency