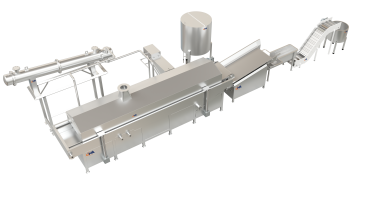

Namkeen Frying Line

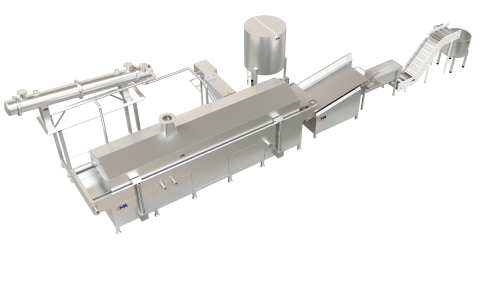

Automated Control

A PLC System with a PLC/Non PLC Interface allows for easy, consistent operation and data management.

Perfect Timing, Precise Temperature

The Frying Line expertly maintains the ideal frying time at the precise temperature, ensuring each batch is perfectly cooked for consistent quality and taste.

De-Oiling/ Cooling Conveyor

A Single-Step conveyor effectively removes excess oil, improving product Cooling for Extending shelf life.

Best Expansion & Minimal oil Pick-up

A pre-heater and vibrating shaker maximize expansion and minimize oil absorption, ensuring light, crispy products.

Precise Frying Control

The system uses a hot oil inlet and continuous filtration for exact temperature and flow control, reducing oil pick-up and enhancing product quality and shelf life.

Features

- Continuous Oil Filter :

Ensures the frying oil remains clean, enhancing the quality of the fried product.

- Automatic oil Level Control :

Maintains optimal oil levels throughout the frying process.

- Cooling System :

Integrated inside the oil tank to manage temperature and preserve oil quality.

- Clean-in-Place (CIP) System:

Facilitates easy and through cleaning of the frying line, ensuring hygiene and efficiency.

- Compact Design :

The frying line's compact design requires minimal floor space while maximizing output.

| Model | UTF-F-300 | UTF-F-500 | UTF-F-1000 |

| Output | 300 kg/hr | 500 kg/hr | 1000 kg/hr |

| Edible Oil Holding Capacity | 400 Itr | 500 Itr | 800 Itr |

| Power Require | 10 H.P. | 15 H.P. | 17.5 H.P. |

| Length & Width | 35 ft X 6.5 ft | 40 ft X 7 ft | 46 ft X 8 ft |

| Fuel (Diesel, Gas, Thermic,Wood, Pellet) | ? | ? | ? |

| Lifting System | Mechanical Reducing type | ||

| Material of Construction | S.S. 304 | ||